In an era dominated by digital dentistry—where CAD/CAM systems and 3D printing promise unprecedented precision and efficiency—traditional casting techniques might seem anachronistic. Yet, even as technology reshapes prosthetic workflows, casting remains a cornerstone of dental lab fabrication, particularly for complex cases, specialized materials, and custom restorations. While digital tools excel at standardization, casting offers unparalleled flexibility, material compatibility, and artistic control. Below, we explore how 18 essential casting-related equipment continues to drive excellence in modern prosthodontics.

Precision Model Creation: The Foundation of Success

Accurate models are critical for any prosthetic workflow. Equipment like the duplicating machine ensures flawless replicas of arches or existing restorations, enabling multiple iterations for multi-unit bridges or implant frameworks. Complementing this, the model trimmer precisely trims plaster or resin models, while a vibrator eliminates air bubbles during impression setting. A lab parallel surveyor guarantees models are perfectly level, ensuring occlusal accuracy. Meanwhile, a dust collector maintains a pristine workspace by capturing debris from grinding or trimming, protecting both equipment and technicians.

Metalwork and Casting: Where Tradition Meets Material Mastery

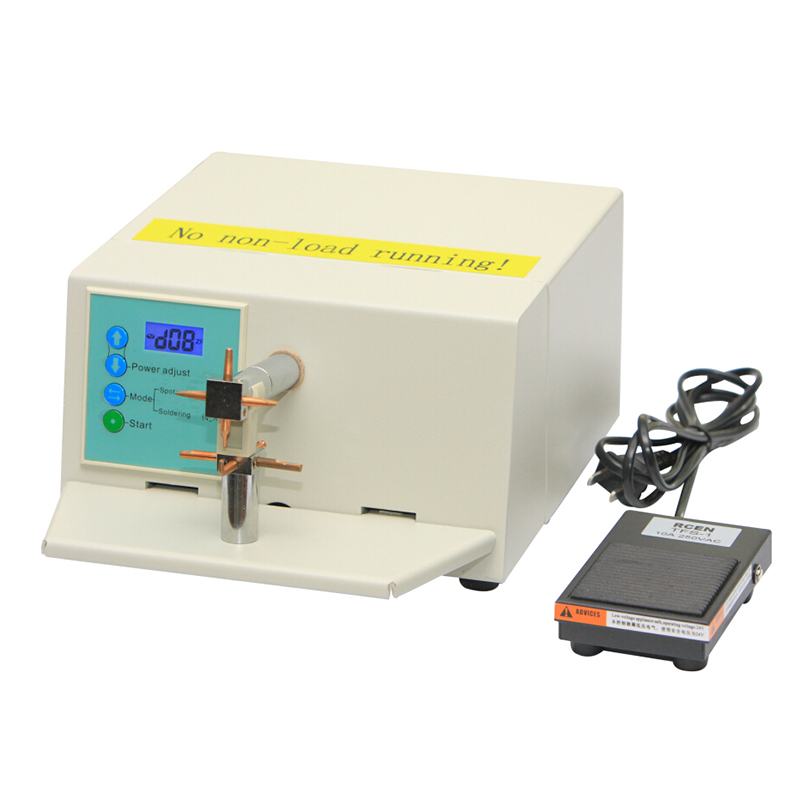

For metal restorations—such as cobalt-chromium crowns or titanium implants—casting remains irreplaceable. The centrifugal casting machine spins molten metal to produce void-free frameworks with uniform thickness, while a wax pattern flask creates intricate investment molds for custom designs. A spot welder joins metal components (e.g., clasps or substructures) with pinpoint accuracy, and the electric dental lab pressure pot applies heat/pressure to cure refractory materials for complex metal-ceramic restorations. These tools shine when milling is impractical, such as with titanium or opaque ceramics.

Processing and Refinement: Bridging Analog and Digital

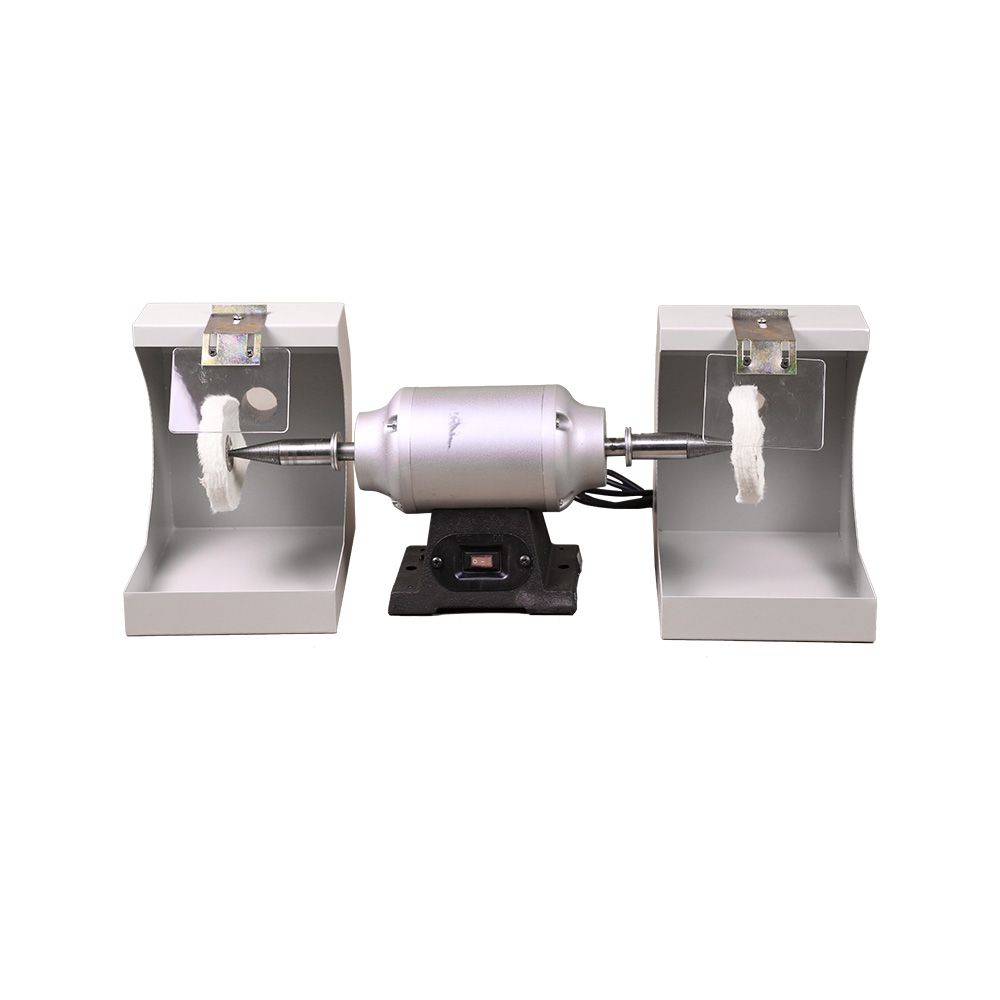

Once cast, restorations require meticulous refinement. The high-speed grinder quickly trims excess material, while a sandblaster machine textures surfaces for enhanced adhesion or aesthetics. For smooth finishes, the polishing lathe rotates restorations to achieve glass-like sheens, and an electrolytic polisher removes microscopic imperfections without mechanical wear. Even in hybrid workflows, these tools ensure cast components meet digital standards—for instance, polishing a cast coping before digitizing it for a porcelain veneer.

Specialized Applications: When Casting Outperforms CAD/CAM

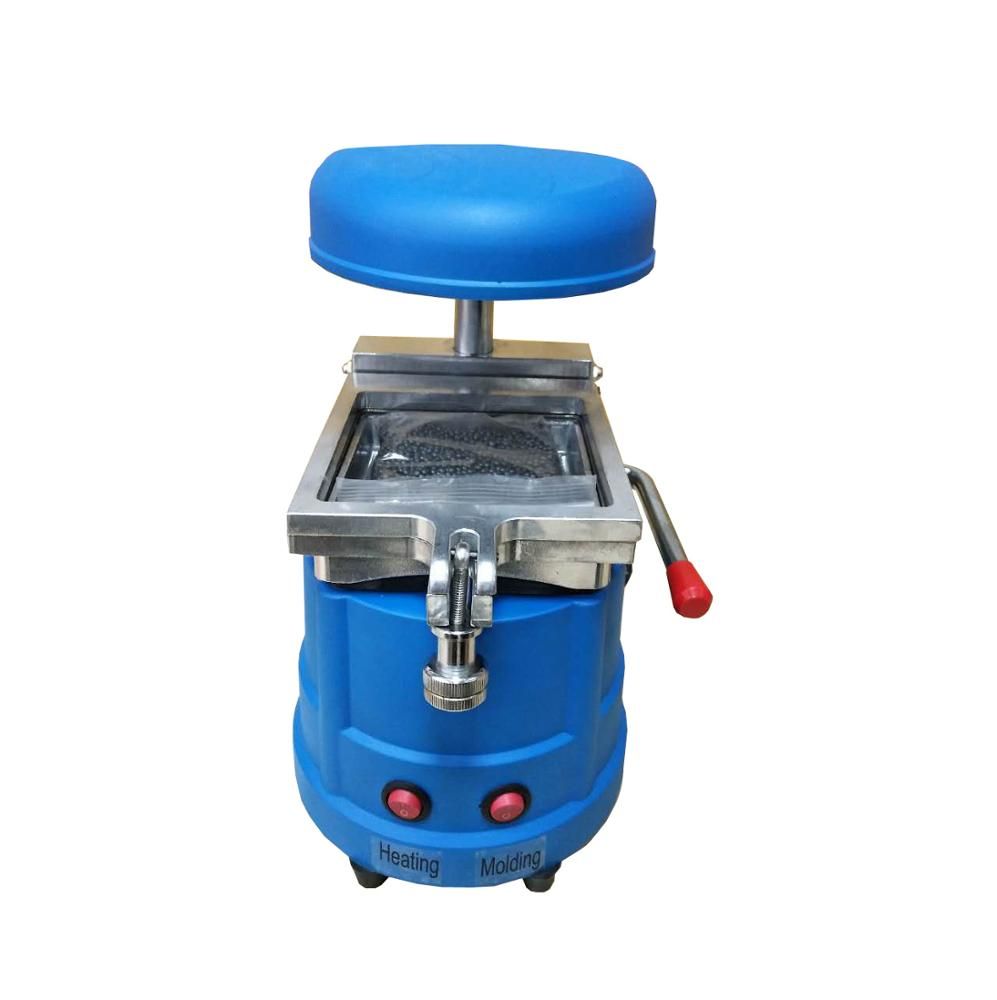

Certain prosthetics demand the unique strengths of casting. The flexible denture injection machine processes thermoplastic materials for seamless, comfortable denture bases, while the vacuum former heater shapes thermoformed appliances like Essix retainers. The pindex dental machine tests occlusion on dentures or implant bars, simulating bite dynamics to perfect fit. For composites or acrylics, the vacuum mixer dental machine eliminates bubbles, ensuring homogeneous structures. These tools address niche needs that digital fabrication struggles with, from customizable flexibility to material-specific processing.

Why Casting Persists in the Digital Age

Casting’s endurance stems from its versatility. It accommodates materials unsuitable for milling (e.g., titanium, certain ceramics), enables cost-effective small batches (ideal for boutique labs), and allows hand-crafted adjustments for lifelike aesthetics. Moreover, hybrid workflows—like designing frameworks in CAD and casting them—combine digital precision with analog adaptability. As long as dentistry demands customization, complex geometries, or specialized alloys, casting will remain vital.

Looking for high-quality dental lab equipment? Dental Laboratorio provides extensive options available. Whether you’re upgrading legacy tools or integrating casting into digital workflows, partnering with trusted suppliers ensures your lab thrives in this dynamic era. After all, the best outcomes often arise where tradition and innovation intersect.